TR2024-077

A Black-Box Physics-Informed Estimator based on Gaussian Process Regression for Robot Inverse Dynamics Identification

-

- , "A Black-Box Physics-Informed Estimator based on Gaussian Process Regression for Robot Inverse Dynamics Identification", IEEE Transaction on Robotics, DOI: 10.1109/TRO.2024.3474851, pp. 4820-4836, August 2024.BibTeX TR2024-077 PDF Data Software

- @article{Giacomuzzo2024aug2,

- author = {Giacomuzzo, Giulio and Dalla Libera, Alberto and Romeres, Diego and Carli, Ruggero},

- title = {{A Black-Box Physics-Informed Estimator based on Gaussian Process Regression for Robot Inverse Dynamics Identification}},

- journal = {IEEE Transaction on Robotics},

- year = 2024,

- pages = {4820--4836},

- month = aug,

- doi = {10.1109/TRO.2024.3474851},

- issn = {1941-0468},

- url = {https://www.merl.com/publications/TR2024-077}

- }

- , "A Black-Box Physics-Informed Estimator based on Gaussian Process Regression for Robot Inverse Dynamics Identification", IEEE Transaction on Robotics, DOI: 10.1109/TRO.2024.3474851, pp. 4820-4836, August 2024.

-

MERL Contact:

-

Research Areas:

Abstract:

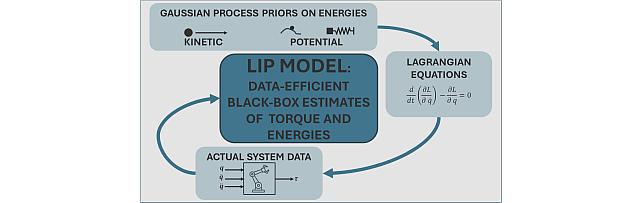

In this paper, we propose a black-box model based on Gaussian process regression for the identification of the inverse dynamics of robotic manipulators. The proposed model relies on a novel multidimensional kernel, called Lagrangian Inspired Polynomial (LIP) kernel. The LIP kernel is based on two main ideas. First, instead of directly modeling the inverse dynamics components, we model as GPs the kinetic and potential energy of the system. The GP prior on the inverse dynamics components is derived from those on the energies by applying the properties of GPs under linear operators. Second, as regards the energy prior definition, we prove a polynomial structure of the kinetic and potential energy, and we derive a polynomial kernel that encodes this property. As a consequence, the proposed model allows also to estimate the kinetic and potential energy without requiring any label on these quantities. Results on simulation and on two real robotic manipulators, namely a 7 DOF Franka Emika Panda and a 6 DOF MELFA RV4FL, show that the proposed model outperforms state-of-the-art black-box estimators based both on Gaussian Processes and Neural Networks in terms of accuracy, generality and data efficiency. The experiments on the MELFA robot also demonstrate that our approach achieves performance comparable to fine-tuned model-based estimators, despite requiring less prior information.

Software & Data Downloads

Related News & Events

-

NEWS MERL Researcher Diego Romeres Collaborates with Mitsubishi Electric and University of Padua to Advance Physics-Embedded AI for Predictive Equipment Maintenance Date: December 10, 2025

MERL Contact: Diego Romeres

Research Areas: Artificial Intelligence, Machine Learning, RoboticsBrief- Mitsubishi Electric Research Laboratories (MERL) researchers, together with collaborators at Mitsubishi Electric’s Information Technology R&D Center in Kamakura, Kanagawa Prefecture, Japan, and the Department of Information Engineering at the University of Padua, have developed a cutting-edge physics-embedded AI technology that substantially improves the accuracy of equipment degradation estimation using minimal training data. This collaborative effort has culminated in a press release by Mitsubishi Electric Corporation announcing the new AI technology as part of its Neuro-Physical AI initiative under the Maisart program.

The interdisciplinary team, including MERL Senior Principal Research Scientist and Team Leader Diego Romeres and University of Padua researchers Alberto Dalla Libera and Giulio Giacomuzzo, combined expertise in machine learning, physical modeling, and real-world industrial systems to embed physics-based models directly into AI frameworks. By training AI with theoretical physical laws and real operational data, the resulting system delivers reliable degradation estimates on the torque of robotic arms even with limited datasets. This result addresses key challenges in preventive maintenance for complex manufacturing environments and supports reduced downtime, maintained quality, and lower lifecycle costs.

The successful integration of these foundational research efforts into Mitsubishi Electric’s business-scale AI solutions exemplifies MERL’s commitment to translating fundamental innovation into real-world impact.

- Mitsubishi Electric Research Laboratories (MERL) researchers, together with collaborators at Mitsubishi Electric’s Information Technology R&D Center in Kamakura, Kanagawa Prefecture, Japan, and the Department of Information Engineering at the University of Padua, have developed a cutting-edge physics-embedded AI technology that substantially improves the accuracy of equipment degradation estimation using minimal training data. This collaborative effort has culminated in a press release by Mitsubishi Electric Corporation announcing the new AI technology as part of its Neuro-Physical AI initiative under the Maisart program.

Related Publication

- @article{Giacomuzzo2023oct,

- author = {Giacomuzzo, Giulio and Dalla Libera, Alberto and Romeres, Diego and Carli, Ruggero},

- title = {{A Black-Box Physics-Informed Estimator based on Gaussian Process Regression for Robot Inverse Dynamics Identification}},

- journal = {arXiv},

- year = 2023,

- month = oct,

- url = {https://arxiv.org/abs/2310.06585}

- }